How Does Cured-in-Place Pipe (CIPP) Point Repair Work?

Posted by William Heinselman on

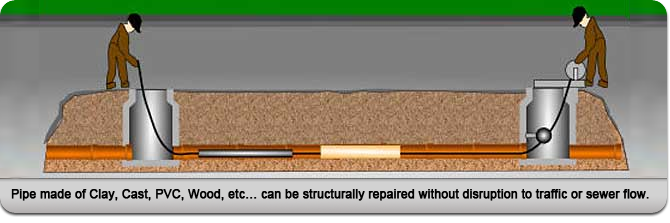

A cost-effective and more practical alternative to sewer replacement, the trenchless cured-in-place pipe (CIPP) point repair method provides structural restoration without digging into the existing pipeline. A jointless technique of renovation, point repair improves flow qualities, and completely eliminates infiltration or exfiltration at the repair location. Point repairs can be installed in pipe diameters from 6 inches to 54 inches and lengths from 2 feet to 30 feet.

The CIPP point repair also only lines areas of the pipe that need repair opposed to lining the entire pipe. Pipeline video inspections accross the US have uncovered that only 6 percent of manhole-to-manhole sewer main actually needs repair. On a 300 foot sewer pipe, this is 18 feet of pipeline! The point repair methods saves both money and time!

The Cured-in-Place Pipe Point Repair Process in Detail

With the CIPP point repair method, multiple point repairs can be installed within only a few hours without line disruption. Access to the pipeline can be gained through the nearest manhole, where the cured fiberglass “tube” is positioned into placed under visual monitoring by a video camera. The point repair is pressed firmly against the inner wall of the host pipeline utilizing air pressure and then cured with an epoxy mixture once in place. The complete product forms a thin, protective wall around the damaged pipeline.

The point repair process begins when a high velocity jetter is used to clear all debris and foreign material out of the pipeline. Video inspection is the next step. A video camera must be used to determine the location and condition of the damaged pipeline. An epoxy mixture is saturated into a mat composed of fiberglass and felt. Then, this mat is wrapped onto a bladder that is inserted into the sewer pipeline, to the exact damage location. The bladder is then inflated to the proper pressure level to couple the repair to the pipe. The bladder is a “flow-through” which means it allows continual usage of the sewer. After the proper curing time (usually 2-3 hours), the bladder is deflated, and then removed ending the point repair process.

The Numerous Benefits of Cured-in-Place Pipe Point Repair

Cured-in-place pipe point repair is very beneficial for a variety of reasons to both plumber and customer.

- Affordable: CIPP point repair reduces the higher price tag that is usually associated with conventional methods of pipeline rehabilitation. This includes costs such as repaving the road, traffic control, labor costs, etc.

- Long Life Span: The minimum life span of CIPP point repair is 50 years!

- Ease of installation: With CIPP point repair installation, the liners can be installed without any service interruption. A complete job can be finished in a matter of hours.

- No digging: Because of cured-in-place-pipe point repair technology, contractors no longer need to cautiously dig while maneuvering around various utilities to locate the area in need of repair.

- No more negativity: The CIPP point repair method greatly reduces the negative effects on the daily routines and lives of individuals, homes, businesses, and traffic in the area. Pollution and unwanted noise are also removed with the cured-in-place pipe trenchless point repair technology system.

If you are looking for cured-in-place pipe (CIPP) point repair experts, then you must contact Express Sewer and Drain in Sacramento. Our plumbers have the knowledge and the experience to remedy any pipe problem that you may be having. We WILL quickly and successfully fix your crumbling pipelines! Contact us today for more information about our services, or to set up a consultation.

Topics: Trenchless Technology, Sewers, Drain Cleaning and Repair

![Repiping Your Sacramento Home [6 Steps]](https://www.expresssewer.com/hs-fs/hubfs/plumbing%20tools%20and%20blueprints.jpeg?width=550)